REPAIRING CIRCULAR SAWS

The complete solution for circular saw repair

We introduce our solution for the repairing of circular saws with tungsten carbide teeth

We introduce our solution for the repairing of circular saws with tungsten carbide teeth

In the professional sharpening sector, every detail counts. Choosing the right machine can make the difference between a profitable workshop and one that falls behind. At ELITE, leaders in sharpening technology, we compare our two back-off grinding machines: the MVB 750 and the MVB 850.

Both models offer the precision and robustness that define our brand, but each is designed for different needs. Whether you are looking for efficient back-off grinding or a complete sharpening solution, this comparison will help you decide which is the best investment for your workshop.

.webp)

Extend the life of your sharpening machine with oil cooling

For the most demanding sharpening workshops that want to keep their ELITE sharpener as new as the first day, the use of pure oil as a coolant is essential.

ELITE, the sharpeners accessible for all types of sharpening workshops.

ELITE was born from a firm conviction: workshops, regardless of their size or resources, deserve quality sharpening machines. In a market where machines were seen as inaccessible and expensive, ELITE chose a different path: designing professional, precise, and most importantly, affordable machinery.

In the heart of thousands of carpentry, metal, aluminum and plastic workshops lies a silent challenge: keeping their circular saw blades sharp. And that challenge is nowadays beyond reach for many due to the high costs of acquiring the necessary machinery.

Complex machines, steep prices, and impossible maintenance requirements have turned blade sharpening into a luxury for many.

But at ELITE, we never saw a luxury. We saw a necessity.

A necessity that merits a solution that’s simple, affordable, and professional.

To provide our customers with the best experience using our sharpening machines, we have created a pack of accessories + consumables to equip the ELITE machines to get the best performance.

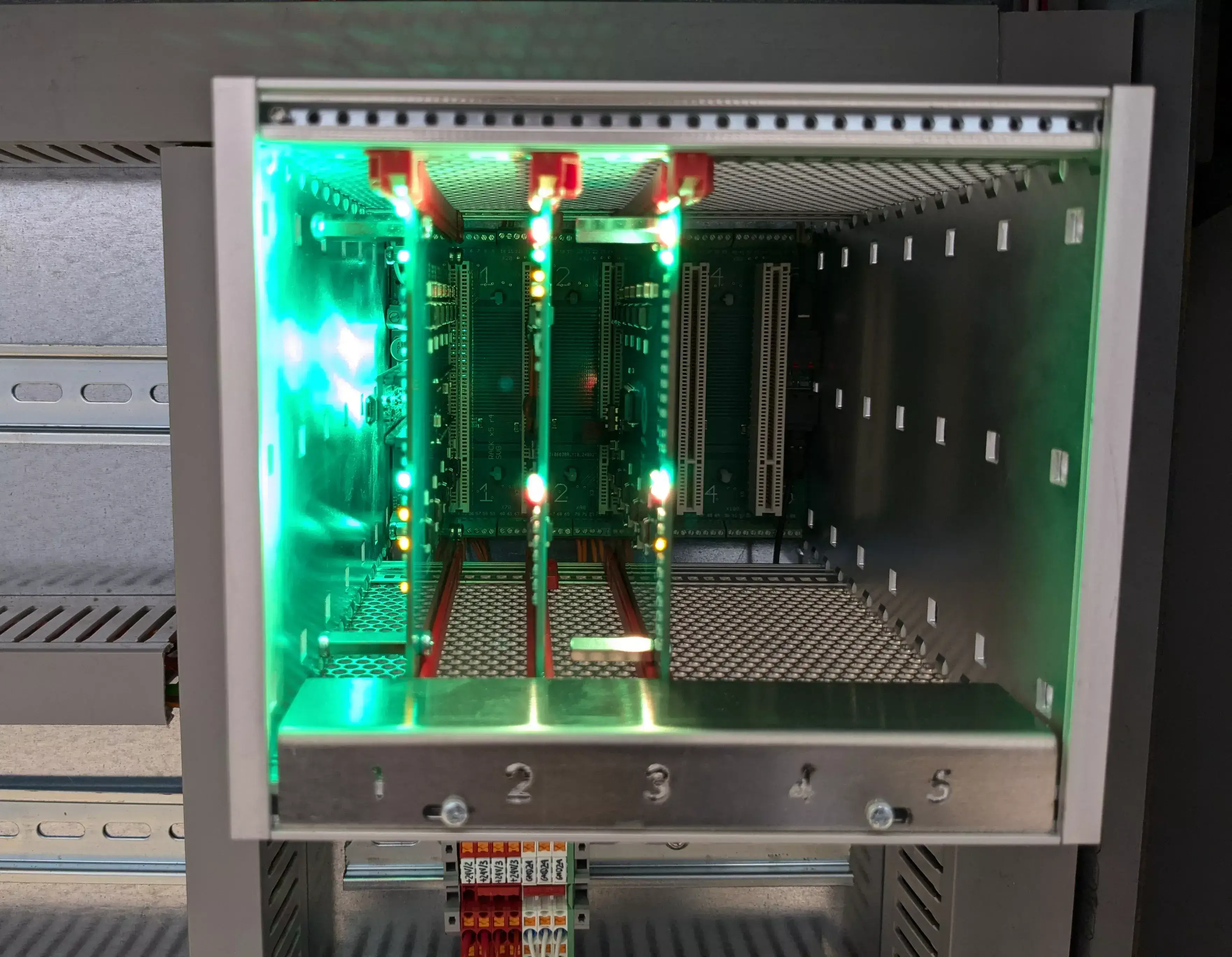

ELITE presents its new development for the CNC control of our machines: the electronic rack system.

ELITE visits several sawmill companies in Indonesia, with the aim of strengthening ties with our customers, presenting our products and understanding their needs first-hand.