Maintenance of bandsaws for sawmill

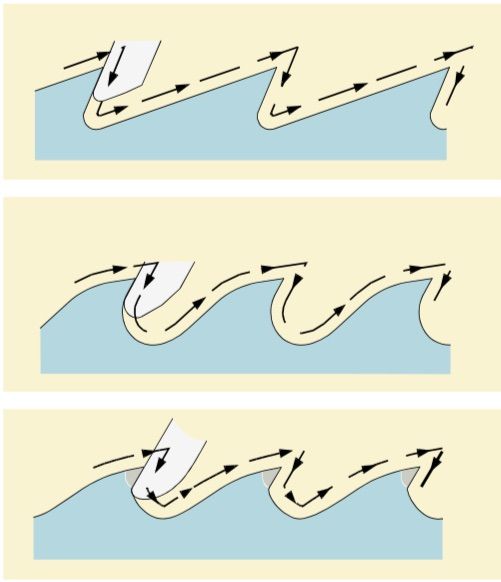

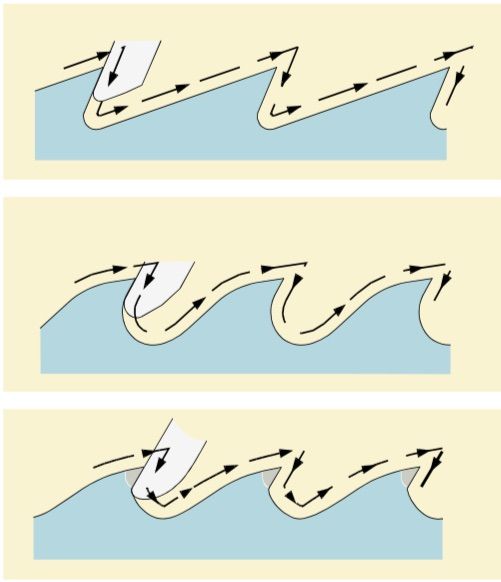

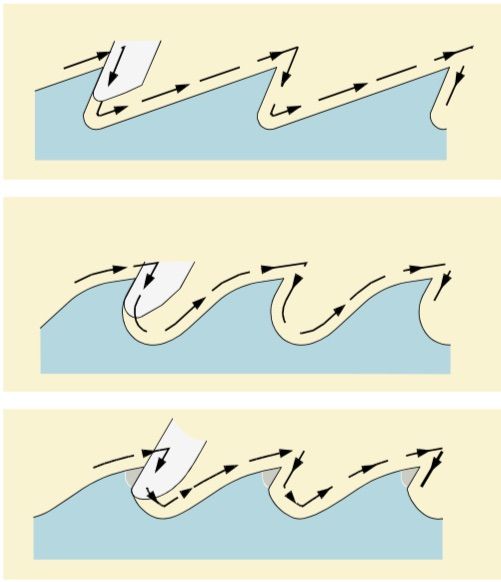

Band saw blades are considered problematic as they are far more fragile than similar machining tools such as circular saw blades, gang saw blades or milling cutters, and simply break off if incorrectly handled.

Band saw blades are considered problematic as they are far more fragile than similar machining tools such as circular saw blades, gang saw blades or milling cutters, and simply break off if incorrectly handled.

Band saw blades are considered problematic as they are far more fragile than similar machining tools such as circular saw blades, gang saw blades or milling cutters, and simply break off if incorrectly handled.

The new version of the sales success machine: the ELITE model CU mini 1200 is finally here.

The ELITE model CU mini 1200 is our smallest series of grinding machines for knives blades sharpening,...

Introducing the new ELITE model MD 650 with the redesigned cooling system

For perfect sharpening of circular saws from 200 to 650mm in diameter

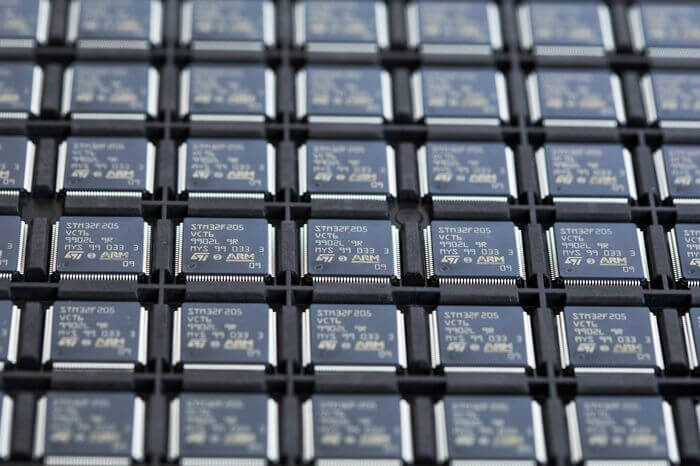

It’s all well known that, during post Covid19 period, the world had some supply chain problems, which also generated price increases. We suffered some of this problems as well, such as problems with steel supply, welding gas, motors, drivers, VFD's and relays. Nevertheless, by large, the biggest supply problem was electronic chips.

At ELITE, we do the design and manufacturing of our electronic boards. Why?

At ELITE we commission all our machines for free at our facilities so that the client learns from how to install it to how to make it work with all its possibilities and get the most out of it.

Do you know that Elite manufactures its own magnetic chucks?

In the beginning, we bought the magnetic chucks for our knives grinding machines, like practically any other grinding machine manufacturer. However we realized that our market, the grinding market, is so small that no manufacturer could understand what we really need: It is not only about magnetic power, but also water sealing, energy saving, precision and without forgetting the cost factor.

Within the sharpening of circular saws with carbide inserts, we can distinguish two different types of sharpening depending on the use that we are going to give to the saw:

In this article we will focus on the sharpening of saws for cutting aluminum.

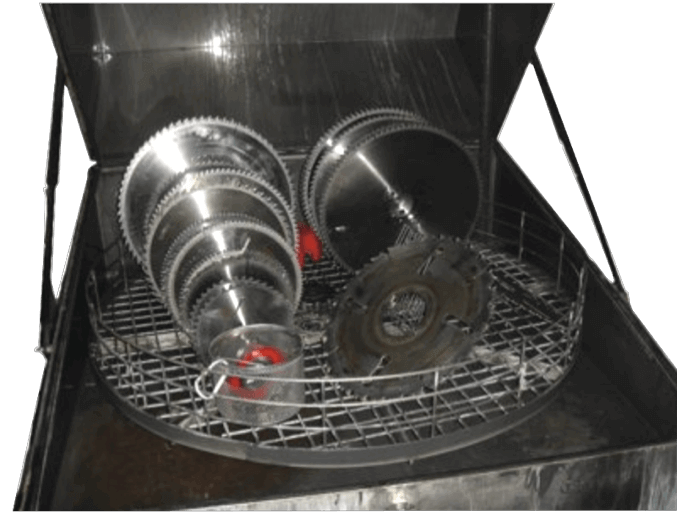

Fortunately, there are more and more saw specialists aware of the importance of cleaning the saws well before putting them in the sharpening machine. That’s because keeping them clean allows us to save on coolant and obtain better precision in sharpening.

In this article, we explain why.